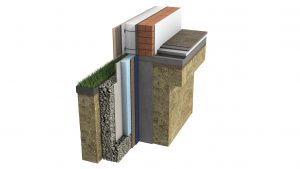

Thermal insulation of foundations from outside

Necessity

The thermal insulation of foundations from outside is necessary for protecting load-bearing structures against the effects of humidity and frost. The most common ribbon-type foundation structures are made of reinforced concrete or bricks. Both types of materials are frost-resistant; if water penetrates these materials and freezes there, the frost resistance of these materials significantly reduces. Correct thermal insulation of foundations from outside and simultaneous creation of hydro insulation layer can protect the foundation against early loss of durability capacities.

Protection of foundations

LLC TENAPORS offers a formed thermal insulation polystyrene foam with reduced water absorption. Such a material in combination with hydro insulation protects the unity of load-bearing structures against ground waters and effects of other humidity sources. Furthermore, polystyrene foam is frost-resistant and its ling-term use does not show degrading of material properties. Moreover, EPS materials show very good thermal technical properties protecting structures against frost penetration. Both these properties protect ground (on which there is foundations of building) against protrusions and structural lowering.

Advantages of materials

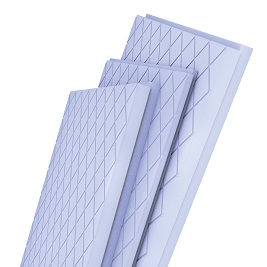

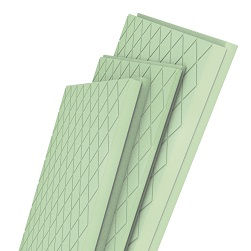

Polystyrene foam for thermal insulation of foundations is formed in special products. Such a technology has three main advantages:

- Reduced water absorption.

- Special semi-stopgap connection for easy mounting and thermal bridge prevention in connection sites.

- Relief for improved material durability against removal from the wall structure.

- Elevated mechanical durability.

Polystyrene foam plates are produced in a way that they are easily treatable on the site and you could construct a uniform thermal insulation layer. The special relief ensures not only additional durability of the thermal insulation system against mechanical effects but also redirection of excess humidity. The thermal insulation material must withstand the ground-created load; therefore, the material is made of high-durability polystyrene foam with long-term load tolerance (exceeding 2.5t/m2).

Mounting

The mounting takes place as follows:

- Preparation and cleaning of foundation.

- Placement of hydro insulation layer.

- Gluing polystyrene foam plates with polyurethane glue.

- Placement of geo membrane in ground.

- Creation of above-foundations layer in the plinth part of the foundations.

Creation of foundation is a necessary step because on a dirty or uneven surface hydro insulation and thermal insulation layer can be placed improperly, failing to secure the required hydro insulation and desired thermal insulation effect. To avoid chemical reactions contributing to decomposing of thermal insulation material, it is advised to use hydro insulation made on water bases. The geo membrane layer is necessary for additional protection of the thermal insulation layer against humidity because in case of excessive groundwaters or rainwater its openings can be used to direct the excess humidity into the lower layers of ground.