Why choose us?

- The physical and mechanical properties of the foamed polystyrene material largely depend on its volume mass. With the higher volume mass, values of the strength parameters also increase, such as compressive, flexural and shear strength, which also determines the usage of the material

- The good insulating properties of the foamed polystyrene material arise from the high content of air pores. The foamed polystyrene material is made of approximately 98% air and 2% polystyrene. The efficiency of thermal insulation materials is characterized by thermal conductivity coefficient “lambda” λ (W/mK), which is one of the lowest in foamed polystyrene materials and ensures the lowest level of heat loss.

- Polystyrene – the formative element of the foamed polystyrene is not a hygroscopic material, and even in direct contact with water it absorbs only a tiny amount of water! Since pore walls are waterproof, the water can merely run through the material or penetrate inside only through the channels between the pores

- They may be continuously used as a thermal insulation material at ambient temperatures of up to + 80°C.

- Foamed polystyrene does not rot, does not serve as a medium for bacteria and is eco-friendly. It is resistant to weak acidic, alkaline and saline solutions but non-resistant to aromatic and halogen containing solvents, esters, ketones, oils or lubricants

Environment and sustainability

Gearing Ltd. TENAPORS operational policy on continuous quality and customer satisfaction index improvement, bringing in the team the best industry professionals, the company has more than 20 years is a stable, reliable partner for our customers and suppliers, while ensuring the company’s compliance with the quality ISO 9001: 2015 and environmental ISO 14001: 2015 standards in the relevant areas.

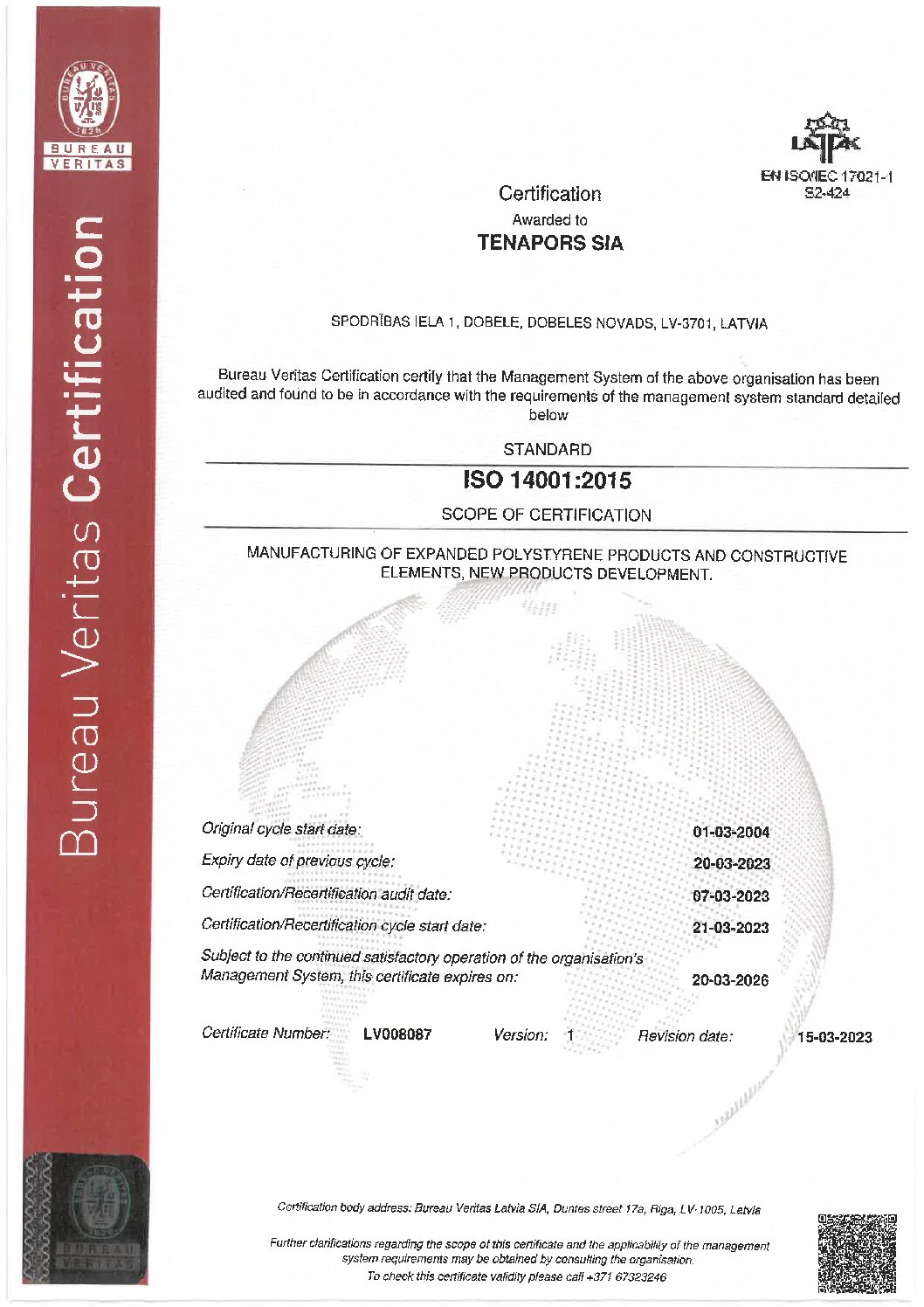

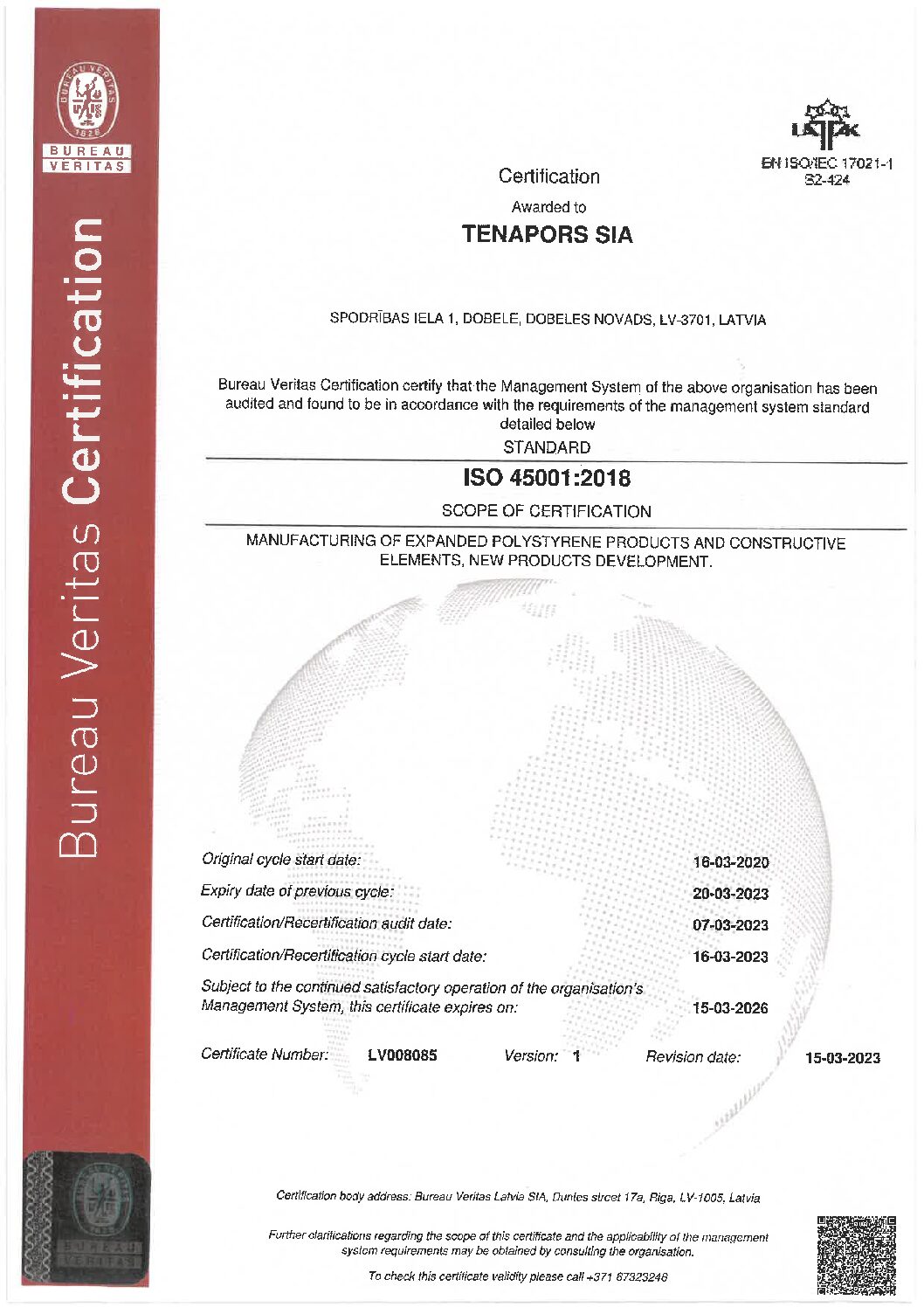

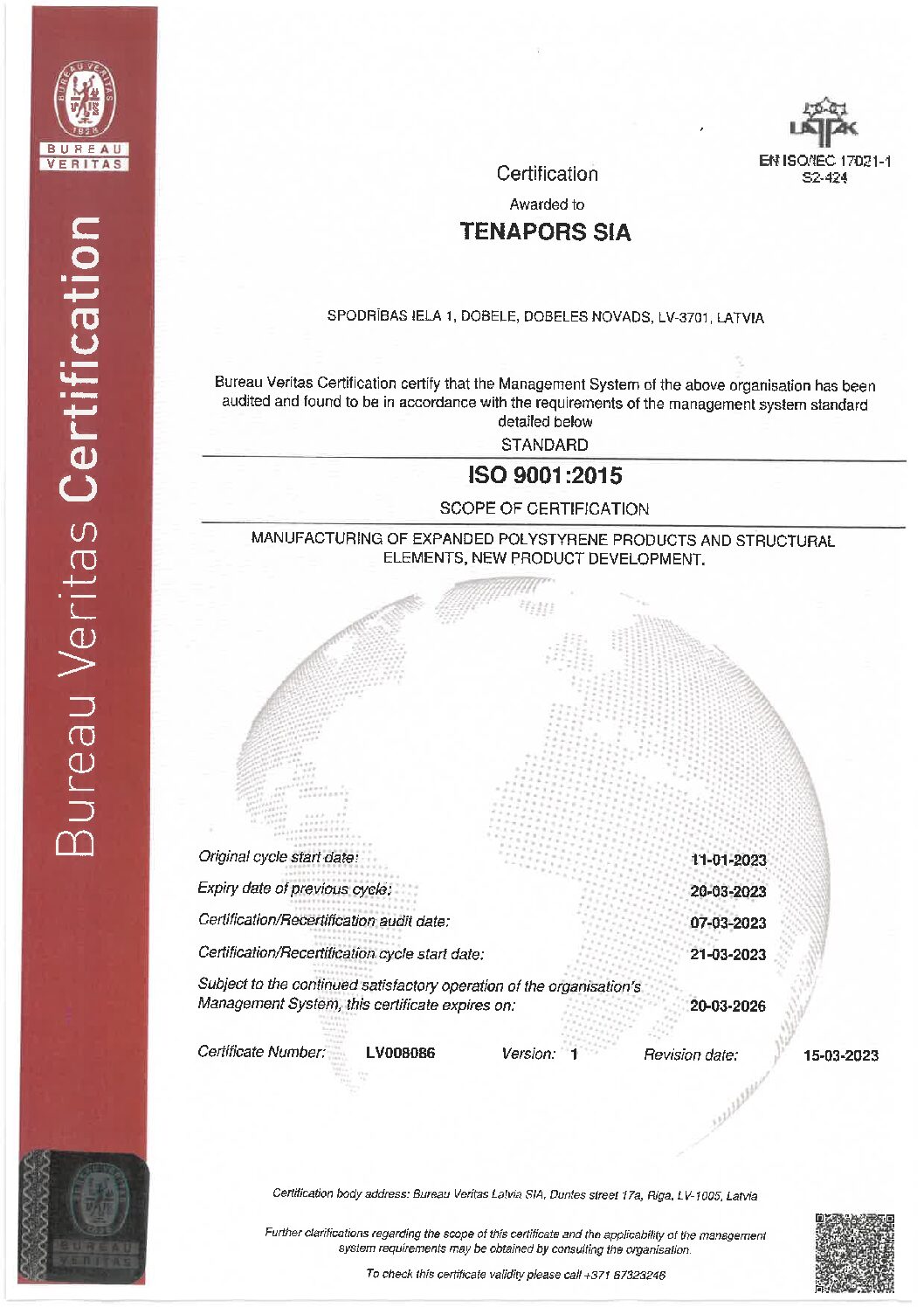

Certificates

To increase the company’s competitiveness of manufactured products in Latvia and global markets, TENAPORS have been guided by international requirements and arranged their production and quality system in accordance with globally recognized standards.

Manufacturing of expanded polystyrene products and constructive elements, new poduct development. ISO 14001:2015

ISO 14001:2015

Manufacturing of expanded polystyrene products and constructive elements, new product development. ISO 45001:2018

ISO 45001:2018

Manufacturing of expanded polystyrene products and constructive elements, new product development. ISO OHSAS 18001

ISO 9001:2015