Insulated foundation concrete forms

System components

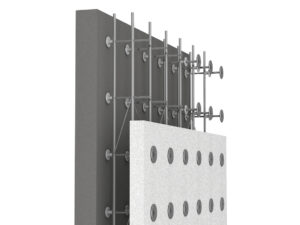

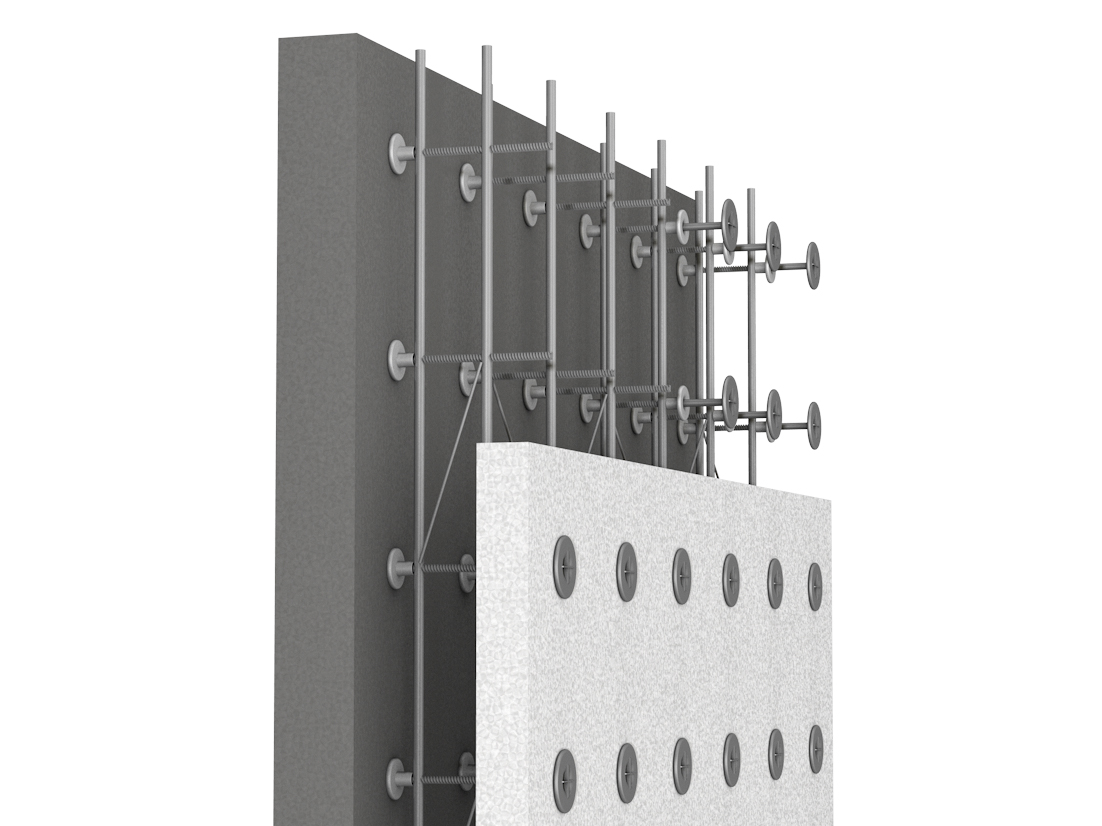

The template system of the load-bearing walls consists of 1.2 m wide templates which can be made with various insulation and polystyrene foam thickness and element length. The template consists of a specially prepared armature carcass and EPS material attached on both ends. The reinforcement serves for two purposes – ensures the required distance between polystyrene foam plates and serves as a concrete reinforcement. The distance of thermal insulation plates can be changed, achieving the desired concrete layer thickness (from 120 to 300 mm). The armature structure consists of longitudinal reinforcement (with diameter of 8, 10 and 12 mm), cross-section reinforcement with 5 mm diameter and diagonal reinforcement with 3 mm diameter. The internal part of the polystyrene foam templates is 50 mm thick, but the external part thickness can be changed depending on the designed thermal technical specifications.

Advantages

Permanent template systems lead to lower workforce expenses and time required for making foundations. Dobele panel – S simultaneously replaces in the construction site three different solutions:

- Polystyrene foam plates serves as templates for pouring concrete and it is not necessary to rent additional templates or to make them out of wood.

- The connection structure of the Dobele panel serves after pouring concrete as concrete reinforcement armature and additional reinforcement works are not necessary.

- Polystyrene foam serves as thermal insulation and additional insulation works are not necessary.

Due to the aforementioned reasons, the amount of on-site works is significantly reduced and, therefore, it is easier to build foundations. Since it is also not necessary to rent templates, the foundations can be made without any rush and no extra investments.

Preparation of foundation

Usually templates are mounted on specially constructed foundations or the concrete plate of the previous story’s floor. To secure a rigid connection between walls and floors, the foundational base (plate) must include vertical reinforcements according to the plan. These reinforcements must be paired or alternately with a 20-30 cm step. The diameter of reinforcements must be in proportion to the diameter of the wall template reinforcement. To secure fast and accurate mounting of the wall elements, one must mount on the foundational base below the internal or both EPS plates a wall element mounting lead – thin-wall U profile (width – 50 mm).

Supporting wall elements

After mounting the first two wall template elements, supporting beams must be mounted, serving the following purposes:

- to fix the conditional and vertical placement of wall elements,

- to secure wall immobility during concreting,

- to protect wall elements against wind load during mounting stage.

To reinforce the connection between wall template elements, joining sites can be supplemented with small wooden or metal parts. To affix the wall template elements to the foundational base or foundations, one must use a steel wire, by attaching the vertical foundational reinforcements with the reinforcement structure of the wall elements. The wire is also used to connect the reinforcement structure of the neighboring wall elements at the upper part of the wall elements. After affixing the first supporting beam, next wall template element must be mounted and supported with a supporting beam. The ends of the wall must be affixed with reinforcements (just like it was described in the section on corner knots). if necessary, the end of the wall can be supplemented with an additional polystyrene foam (EPS) sheet or use only a plank.

Horizontal reinforcement

Mounting the wall template elements, horizontal reinforcement is required. Ø8 bars must be paired with 800mm step. The reinforcement must cover the whole wall. Bars must be placed on the wall EPS element reinforcement structure. If bars are shorter than the wall to be reinforced, an overlap must be made. The horizontal reinforcement must be embedded in the wall template elements along with the mounting works, that is, when mounting several wall elements, bars are introduced therein; when mounting new wall template elements, bars are moved further along.

Concreting works

The concrete mass can be poured in the wall templates from a freely chosen corner of the building smoothly moving in one direction (clockwise or counter-clockwise) around the wall perimeter. The concrete mass is filled in several steps, each 30-40 cm thick. The concrete mass should be filled in the template not closer than 60 cm from the corner of the building. One must pay attention to avoid slushing concrete on the upper part of the wall polystyrene foam plates. Cover these with a cover, e.g. polyethylene film, fabric or adhesive tape. After pouring works, do not vibrate the concrete with deep vibrator. Instead use more simple methods, hitting with a hammer on a wooden stick or armature bar or using a rubber hammer to hit a wooden spacer on a polypropylene nuts – this will allow you to get rid of unwanted air bubbles.